Guidance on testing options for ASTM E84

|

When testing a material for ASTM E84 you are presented with three different testing options, Unadhered, Adhered to GRC and Adhered to Gypsum. These options correlate to the end installation of the material. Depending on if it is for wallcovering, headboard, wrapped panels or something else there are different testing options that apply. |

So how do you know if Unadhered, Adhered to GRC or Adhered to Gypsum is the best testing option for your material? We’ve put together a quick reference guide of the testing options, along with some more information on ASTM E84 testing and the acceptance criteria.

ASTM E84 – Quick Reference

| ASTM E84 Options | Application |

| Unadhered | For wallcoverings or panels that are wrapped and/or not adhered by direct glue application to the wall/substrate. |

| Adhered to GRC | For applications where the material is adhered to a non-combustible substrate. |

| Adhered to Gypsum | For applications where the material is adhered to drywall. |

What is the purpose of ASTM E84?ASTM E84, also referred to as “E84”, is the standard test method used to assess the surface burning characteristics of a material used for interior wall and ceiling finishes, with results measured by Flame Spread Index (SFI) and Smoke Developed Index (SDI). The purpose of the test is to determine the relative burning behavior of a material and assign a class / grade based on the testing results (acceptance criteria outlined below).

|

|

How is ASTM E84 testing performed?

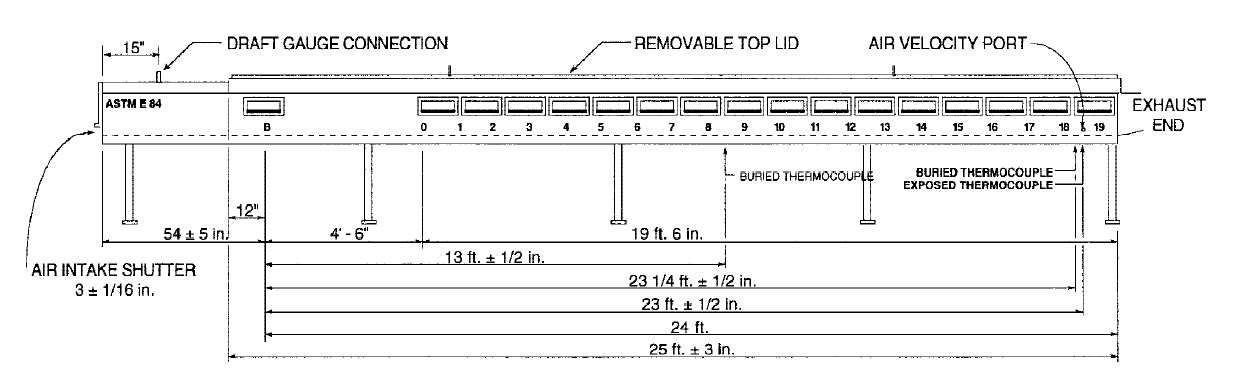

The surface burning behavior of a material is measured by Flame Spread Index (SFI) and Smoke Developed Index (SDI), and is performed inside a 24” x 24” wide tunnel (often called a Steiner Tunnel). The sample is mounted to the removable top lid of the tunnel and is exposed to controlled air flow, or forced air, and two burners providing 89kW of energy, adjusted to spread the flame along the entire length of the sample. The progress of the sample burning is observed through viewing windows installed on the side of the tunnel. A Light Obscuration meter is used to measure the optical density to determine smoke developed. Software records and computes a variety of data and generates the FSI and SDI. The FSI and SDI are used to establish a scale for the rate at which flame spreads and smoke develops during the ASTM E84 test. Based on the FSI and SDI a class rating is assigned to the material.

ASTM E84 Acceptance Criteria

| Class | Flame Spread Index | Smoke Development Rating |

| Class 1 or A | 0 – 25 | 450 maximum |

| Class 2 or B | 26 – 75 | 450 maximum |

| Class 3 or C | 76-200 | 450 maximum |

Material classification of fire performance is based on the test results in accordance with the Life Safety Code, NFPA 101 Section 10.2.3 and the Standard Building Code (issued by SBCCI) Section 704 and/or Uniform Building Code (UBC) (issued by ICBO) Section 4204 and Basic Building Code (issued by BOCA) Section 922.5.3.

More on the Steiner Tunnel

Name: Steiner Tunnel or Steiner Tunnel Test

Purpose: Widely used method to determine the surface burning behavior (fire propagation and smoke development) of building materials of exposed surfaces such as walls and ceilings.

History: Developed in 1944 by Al Steiner of Underwriters Laboratories. Incorporated as a reference in North American standards for materials testing such as ASTM E84, NFPA 255, UL 723 and ULC S102.

Apparatus Description: The tunnel’s roof is a noncombustible horizontal box or tunnel, in a section 7.3 meters (24 ft) long and 0.56 meters (1.8 ft) wide. The tunnel is as wide and long as the test specimen, and 0.305 meters (1.00 ft) high. The apparatus is equipped with two gas burners providing a flame intensity of 89 kilowatts, and air and combustion products are moved through the tunnel by a ventilation system at a controlled velocity of 73 meters (240 ft) per minute.

US Vs. Canadian ASTM E84 Testing

The main differences between the US method ASTM E-84 and the Canadian method CAN/ULC-S102 have to do with the mounting of the test samples in the Steiner Tunnel and the number of samples tested.

ASTM E-84 is performed with the sample mounted to the top of the testing chamber (as described above) and a single sample is tested. CAN/ULC-S102 requires certain samples to be mounted to the floor of the chamber. CAN/ULC-S102 also requires triplicate testing, or three samples tested independently.

Technical Details from ASTM

See more on ASTM’s website here: https://www.astm.org/Standards/E84.htm