Why Choose an Accredited Lab?

From development to final product, textiles are tested for a seemingly endless array of properties by any number of different parties. From a machine operator using a wyzenbeek machine on the mill floor to a lab technician using the same machine in an accredited laboratory, the avenues for obtaining test results are vast. So why choose one over the other?

Some fundamental questions may begin to expose the answer:

|

|

The answers to the questions above range from “likely not” to “absolutely not.”

What Separates an Accredited Lab?

When it comes to excellence for laboratories internationally, the bar is set by the ISO/IEC 17025 standard. ISO/IEC 17025 specifies the general requirements for the competence, impartiality and consistent operation of laboratories and is the standard that accrediting organizations, like the American Association for Laboratory Accreditation (A2LA), use to evaluate laboratories globally. Labs seeking accreditation are audited to ensure that they possess, among other characteristics, the following:

- A robust quality system & quality assurance procedures

- Precisely calibrated and properly maintained testing and environmental conditioning equipment

- Experienced, proficient and highly trained staff

- Accurate recording and reporting procedures using the most current and relevant testing procedures

ISO/IEC 17025 accreditation ultimately ensures that when an accredited lab provides a certificate of testing, the results are precise, trustworthy, recognized internationally and, most importantly, admissible in a court of law. They can be looked to with confidence to make sound judgments during the design process or to properly assess and mitigate risk when selling or specifying products into the marketplace.

What About Non-Accredited Labs?

In contrast, non-accredited labs aren’t required to adhere to any of the standards listed above. They can place their fabric samples that may or may not be cut to the right size on a potentially non-calibrated machine in environmental conditions that don’t meet the specifications of the test standard and then interpret the results however they’d like.

The situation above is a worst-case scenario and is not always what occurs in non-accredited labs however the questions that arise with non-accredited test results are precisely the reason that such results cannot be used in a court of law. Utilizing a laboratory accredited to perform the test method needed removes the uncertainties. In a field claim or in the event of a catastrophe, you’ll want to be able to provide an accredited result proving that proper testing was done prior to selling or specifying a fabric into the marketplace.

So when the mill says that their pattern passes 100,000 cycles, ask them to prove it. The next time you find yourself evaluating a fabric swatch, ask how those results were obtained.

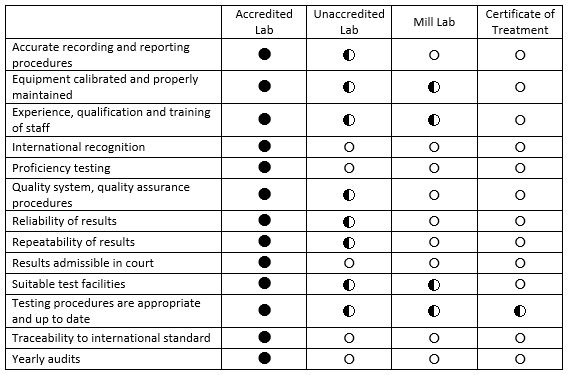

The Differences

To help visualize the differences between the various lab types, the table below lays out the important characteristics of laboratories and the likelihood of them occurring in each lab type:

Interested in utilizing ISO/IEC 17025 A2LA-accredited (cert. 3193.01) testing? Contact us today!